Butterfly valve seat

Features:

Rubber: Good sealing properties and relatively low price

PTFE: Corrosion resistant, high temperature resistant, good anti-adhesive properties

Metal: High strength, good wear resistance

Synthetic materials: Good mechanical properties, good wear resistance

We're here to help:

Easy ways to get the answers you need.

Parameter:

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

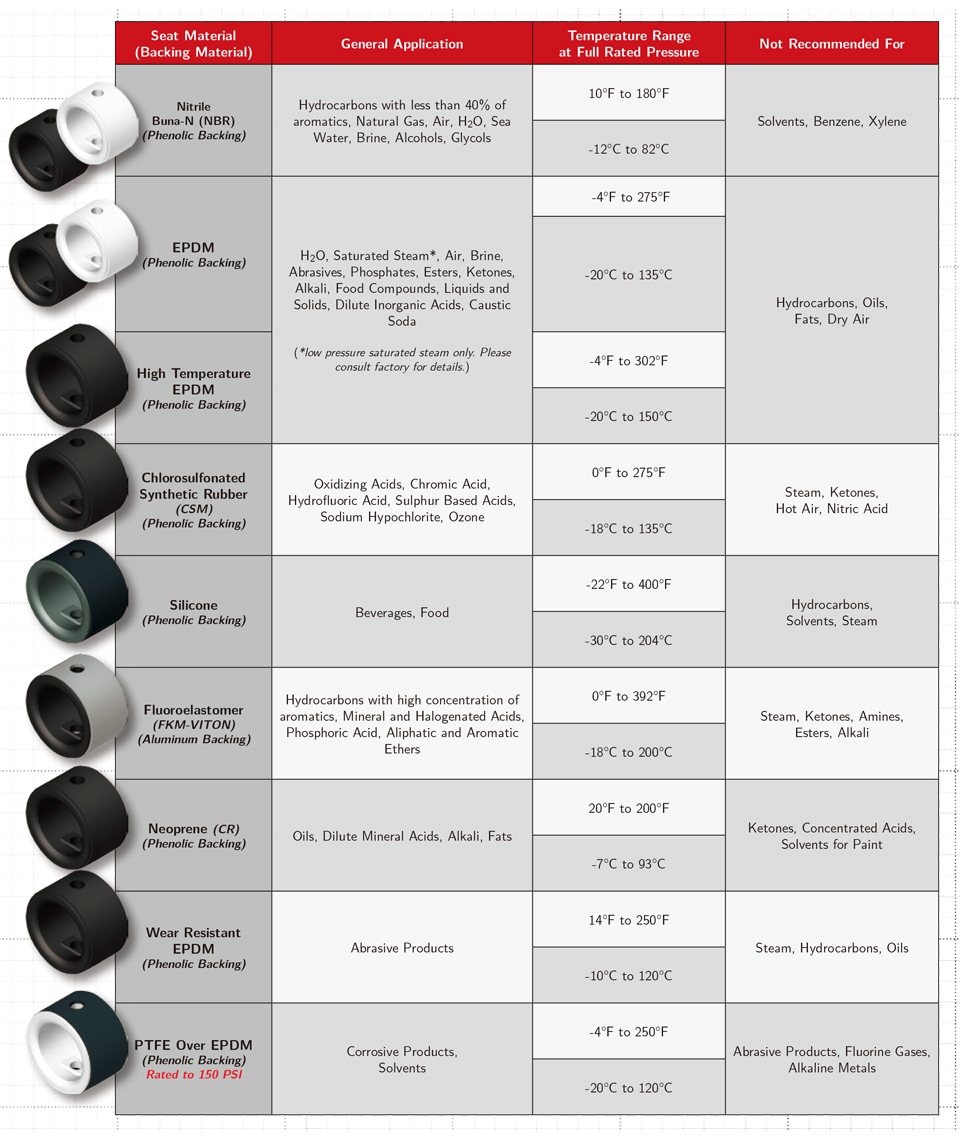

The main materials of butterfly valve seats are as follows:

1. Rubber:

Butterfly valve seats made of rubber have good wear resistance, acid and alkali resistance, corrosion resistance, and sealing performance, and are suitable for low-pressure, room temperature media, such as tap water, sewage, etc.

2. PTFE:

PTFE material butterfly valve seat has excellent corrosion resistance, high-temperature stability, and good anti-adhesive, suitable for corrosion-resistant media, high-temperature media, such as acid, alkali, salt, etc.

3. Metal:

Butterfly valve seats made of metal have high strength and wear resistance and are suitable for hot and cold water, gas, oil and other media.

4. Synthetic materials:

Butterfly valve seats made of synthetic materials have good mechanical properties and wear resistance and are suitable for media under high temperature and pressure, such as petroleum, chemicals, gases, etc.

The advantages of different materials are as follows:

1. Rubber:

Good sealing properties and relatively low price.

2. PTFE:

Corrosion resistant, high temperature resistant, good anti-adhesive properties. 3.

3. Metal:

High strength, good wear resistance

4. Synthetic materials:

Good mechanical properties, good wear resistance.

Therefore, different materials of butterfly valve seats are suitable for different media and working environments. Choosing the right seat material can ensure the sealing and service life of the butterfly valve.

Case:

WEIZIDOM Group specializes in pipeline fluid systems: R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

Application:

Butterfly valves are used in a wide range of applications in various industries due to their simple structure, low cost, and ease of operation. Some common applications of butterfly valves include:

1. Water supply and treatment:

Butterfly valves are commonly used in water supply and treatment systems for regulating the flow of water, controlling pressure, and isolating different parts of the system.

2. HVAC systems:

Butterfly valves are widely used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of air and controlling temperature and humidity.

3. Chemical processing:

Butterfly valves are commonly used in chemical processing industries for regulating the flow of various chemicals and fluids, controlling pressure, and isolating different parts of the system.

4. Food and beverage industry:

Butterfly valves are used in the food and beverage industry for regulating the flow of various liquids and gases, controlling temperature and pressure, and preventing contamination.

5. Oil and gas industry:

Butterfly valves are used in the oil and gas industry for regulating the flow of various fluids and gases, controlling pressure, and isolating different parts of the system.

6. Power generation:

Butterfly valves are widely used in power generation plants for regulating the flow of steam and gas, controlling pressure, and isolating different parts of the system.

Please fill in your procurement needs and contact information

.jpg)